How to make an icebreaker with your own hands

Making an icebreaker with your own hands, you can provideitself a reliable helper for ice fishing for the entire winter season. If you can make a hole in thin ice with an ordinary ax or a peshmock, you can hardly make a convenient neat hole in a meter thick, using inefficient tools. Therefore, the actual question for many fishermen remains the question of how realistic it is to make ice drills for fishing with their own hands.

Mechanical ice screws

During the operation of motorizedA critical role is played by strict adherence to safety rules. Of particular importance is the selection of the appropriate fuel. Therefore, giving preference to this option, the choice should be stopped only on the fuel brands recommended by the manufacturers.

How to make an icebreaker yourself?

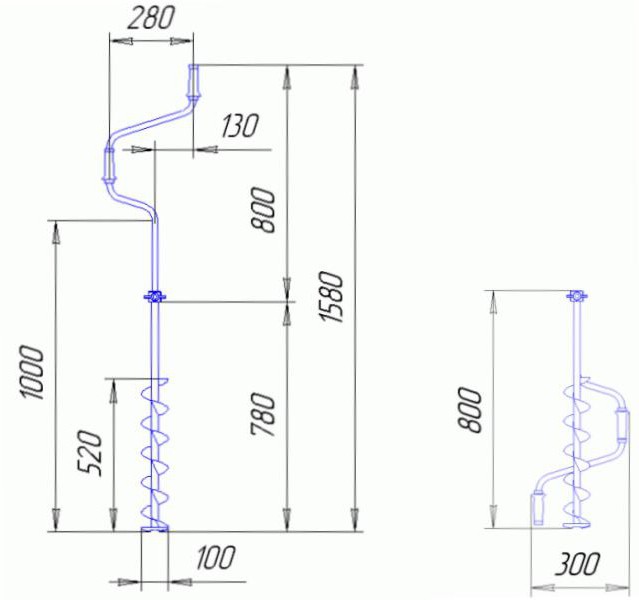

The basis of a simple self-made icebreaker ismetal tube, on which a wound band of a spiral type is fixed. Coping with the manufacture of a self-made auger is difficult, but still real. All the complexity consists in the need to work on turning equipment, access to which is not available for many average anglers. As for the rest of the small elements of the self-made icebreaker, they can be made only by a professional turner with experience.

Classic icebreaker, with your own handsmade, is a durable large-sized drill that can be operated either manually or with a gasoline or electric motor.

All self-made ice drills are conditionally divided intoseveral groups. Some tools are manufactured on the basis of factory models, which are subject to modernization. Other anglers prefer to create such a tool manually from scratch.

Stages of making a homemade ice ax

To make an icebreaker with your own hands, you must act according to the following instructions:

- In the beginning, you should spend enough time onthen, to find a really suitable metal tube of sufficient diameter. One end of the tube will be used as a handle or a swivel, and the opposite one will be used as an auger.

- A more difficult stage is the creation of a foundationfor fastening knives. Here it is better to turn to a skilled locksmith or turner for help, which will not only create a sketch or mock-up of a future design, but also embody the idea into reality.

- To simplify the task of fixing the screw parts, it is better to make them as short as possible, welding to the pipe, and also reliably connecting with each other.

- The final part of creating an icebreaker with your own hands consists in assembling all the constituent parts, fixing them, grinding the surfaces and painting the finished product.

We make the icebreaker from the chain saw by our own hands

If you want to make homemademotorized ice drill as a basis, you can take the factory manual tool or use a screw-turned screw on the lathe itself. As an assembly for the modernization of a hand-held drill, an inexpensive Chinese chainsaw is suitable. It will also require the manufacture of a simple nozzle to connect the manual and mechanical components of the future unit. You can cut it yourself or buy it in a specialized store.

Manufacture of motorized icebreakers based onchainsaws will significantly reduce the time to drill even the deepest holes. In general, among the advantages of this rather unusual solution is worth noting:

- high drilling speed;

- excellent performance of the unit;

- significant savings in cash compared with the acquisition of the factory mechanized model;

- preservation of extra strength, nerves and own health.

Knife sharpening

Creating an icebreaker with your own hands, great attentionshould be given effective sharpening knives. The procedure is to remove the thin metal layer at the required angle. The quality of the cutting edge will depend on the convenience of operation of the future product.

Sharpen knives for self-made ice drillIt is recommended on specialized turning and grinding machines. In this case, it is better to abandon the initiative and experiments, immediately turning to an experienced experienced specialist.

In the process of sharpening knives is not only giventhe necessary sharpness, but also all kinds of errors, jags and burrs are removed. If the sharpening is required knives installed on a makeshift icebreaker, which was already in use, then you can turn to the grandfather's method, using a grinder with abrasive wheels. At the same time, the main condition for sharpening knives is slow work and extremely careful handling of the tool.

What if the knives of a makeshift icebreaker refuse to enter the ice?

Such a situation is oftenfishermen who made a ring icebreaker with their own hands, and those who purchased the factory tool. All sorts of tricks, for example, the selection of appropriate pads and washers, quite rarely allow to solve the problem. After all, its root lies in the improper removal of burrs and insufficiently careful processing of the cutting edge of the knives when manufacturing or sharpening the tool.

In reality, solving the problem is not so difficult. It is enough to take advantage of the usual strong knife, having removed by a back party of its edge all acting errors. Finally, the knives can be gently processed with sandpaper.