Composite processing: gradual improvement of the material

Composite (composite) materials, they are also composites - artificially created by man products, received their name for a reason.

The composition of such a product includes severalmaterials with different characteristics, the combination of which gives rise to a new composition. As a result, the composite panels assign themselves the properties of each of the components, and therefore have improved performance characteristics.

The world of composite products

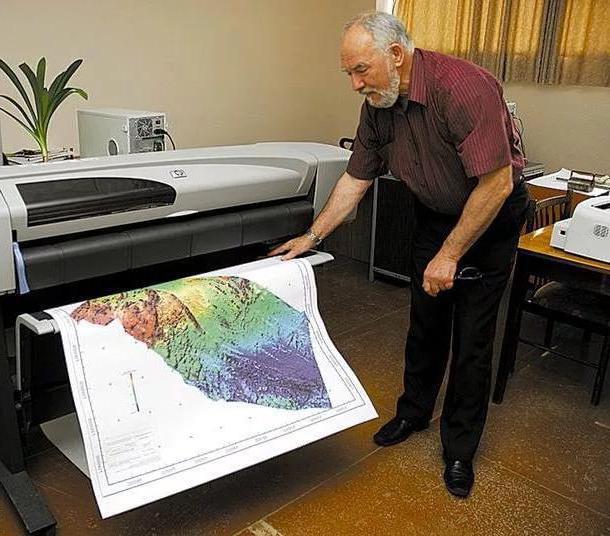

Production and processing of composite - labor-intensivemulti-stage process. Composites require special modification, both in the production process and immediately before installation. All processes related to the manufacture and improvement of parts are carried out on special high-tech machines, thanks to which the process passes faster and better.

Specialists in the field of artificialmaterials argue that the number of combinations of composite materials is unlimited. The composite in the form of plastic panels has already proved itself in the construction market. Such products are in demand because of the low price, resistance to mechanical influences, attractive appearance and extensive field of application.

Scope of composite materials

The combination of wood and polymer makes it possible to obtain a new material - a wood-polymer composite, which is actively used in the construction and finishing of internal and external surfaces.

Composite filling material hasa special density and successfully used in dentistry. Its properties are due to a three-component composition consisting of a polymer, a filler and a bonding layer. The main feature of this material is the possibility of repeatedly adding a solidified layer of matter to the desired shape of the tooth.

The aviation industry also does not do withoutuse of composites. Using composite panels on a metal base, scientists create spacecraft with a weight several times less than conventional steel. So the aerodynamic parameters of the flying body are increasing.

Features of processing composites

Mechanical treatment of composites and specificityfinishes - these are the main features of the material. All actions are carried out in conditions of strict control on special grinding and milling machines, where powerful laser and steel cutters give the products the necessary form. Industrial processing conditions allow to achieve high quality materials. It is impossible to treat the surface of any building material, finishing it to perfection by hand, and due to incorrect work you can get a detail with inaccuracies that may prove to be defective.

Composite processing requires special knowledge and skills. The installation of such products is done by specialists using professional equipment.

In the case of facing the facade of a building or decorationan advertising stand, a composite block will have to be cut. Composite processing is the task that the milling cutter will best handle - a special tool with which you can easily cut the material, avoiding chips and cracks.

Subtlety of milling

A good result in working with compositematerial can be obtained only in the case when you have thought of still at the stage of design work: processing of a composite, a tool, a drawing - everything should be perfect. By milling a detail, you can get a designer masterpiece in the form of an unusual wall panel.

The use of composite materials and options for their processing are closely intertwined with art. So, an experienced milling machine is able to create even pictures that are doomed to success.

Having a sketch on your hands, you can cut out the materialanything, and special machining of the composite will give the construction a new perfect look. With the help of such a machine it is possible to make wood carvings, give the workpiece any shape, outline the contours.

Modern milling machines from their relativesFrom the past, only the name remains. New technologies have captured the world, and now the milling machine is able to perform all stages of processing composites of any type per person.