How to build a formwork with your own hands?

Do not build a shutter yourselfit is difficult, however, to be responsive to this process, since it depends on the element mentioned, how strong your building will be. It should be noted that the presented construction can be removable and non-removable. The first option is much easier to build. For work you will need wooden boards, stakes and mastic, which is coated with the internal surface of the structure. In this case, the aboveground part of the base will be smooth and beautiful.

To properly build a formwork with your own hands, you should follow the following action plan:

- we put in the ground wooden blocks, which will serve as supports;

- to them we nail the prepared boards or shields with the help of nails, after which, without fail, we check their verticality level;

- from the outside of the structure we install spacers that will give it rigidity;

- We check the correctness of the geometric shapes and dimensions of the structure.

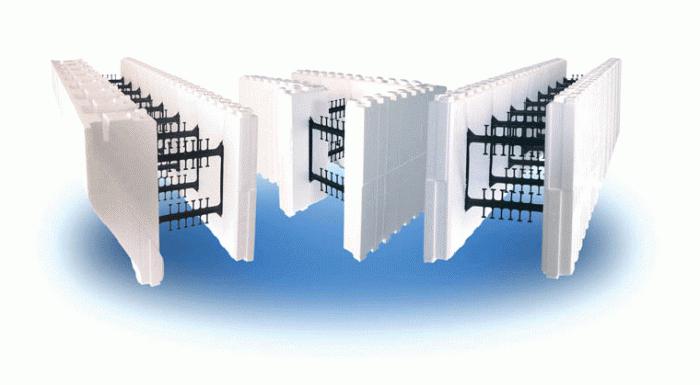

Now consider the technology of construction of a non-removable structure. Its dignity is that it makes the walls stronger, besides, eliminates the need for additional insulation of the building.

So, most often a fixed formwork with your own handsis built of expanded polystyrene blocks. Each element has grooves due to which it is attached to the previous one. Naturally, in this case, you need a lot of reinforcement bars. Install blocks should be on the finished underground part of the base, covered with a waterproofing film. In it, you need to pre-embed the reinforcement, which later will be put on formwork.

After 3-4 layers of blocks are already exposed,You can start pouring concrete with simultaneous ramming. The last row of elements should be filled only half, and the grout of the mortar must be inside the formwork. Fittings and concrete must be of very high quality. Only in this case the building will be strong and stable.

It should be noted that, in addition to the insulation of the walls,the said structure allows the living room to "breathe". In addition, for the construction of such formwork, you do not need special equipment, the rent of which, as a rule, is quite expensive. Thus, you will save money and speed up the process of erecting the building.